- +9221-34966165

- service@uespak.com

Industrial Automation

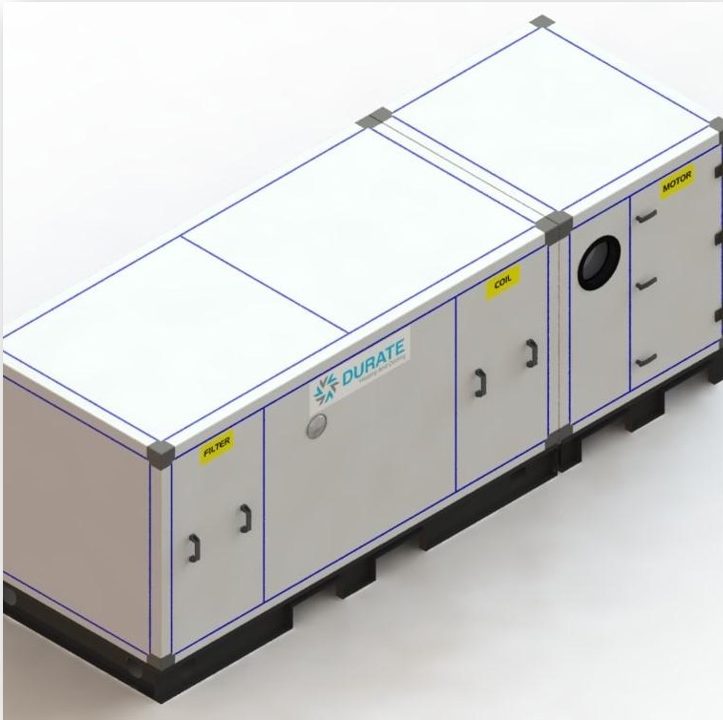

Client: ICCBS, Karachi University

System: AHUs & Condensing Units

- Developed programming for S7-1200 PLCs for each Air Handling Unit (AHU) and its corresponding condensing unit to regulate area temperature and relative humidity (RH) by controlling compressors, heaters, and fans. The PLC also monitored system alarms, including refrigerant low pressure, high pressure, electrical thermal overload, AHU fan failure, electrical phase sequence, high area temperature, RH, and loss of room differential pressure. Additionally, a door interlock system for cleanrooms was implemented using the S7-1200 PLC. All HVAC parameters, including alarms, trends, and system graphical user interface (GUI), were displayed on a 10” Weintek HMI as well as on Winlog Pro SCADA software from Sielco Sistemi.

Client: Bahria Town Karachi

System: Wireless Lightning & Fountain Control System for Golf Course

Summary:

- Installed one master station with 41 slave stations at different location on a Diameter of around 1km.

- Wireless communication over zigbees to communicate master station with slave stations.

- installed Fatek PLC in every station to control Lights, Fountains & Pumps of different golf courses

- System provide monitoring of 3 Phase Voltage, Current, Power Consumption of individual Station.

Following displays have been provided

- 12″ Weintek HMI

- LCD TV (With Wireless Remote)

- Tablets

- Remotely Over the Internet.

Client: USA based Client

System: Emergency Indication System

Developed program for the ABB Safety Pluto PLC to provide clear status indications during various emergency situations within the building. This system monitors critical parameters, such as pressure levels and gate positions, ensuring that relevant information is readily available to personnel during emergencies, thereby enhancing safety and response effectiveness.

Client: Dynea Pakistan Limited

System: Formaldehyde Manufacturing Plant

- Providing a Service Level Agreement for Siemens WinCC SCADA software v7.4, integrated with multiple S7-400 PLCs. The SCADA system offers monitoring and control across three different PCs and oversees the entire formaldehyde manufacturing process, managing over 400+ I/Os.

Client: Hilal Foods

System: RO Plant

Developed a program for the Mitsubishi PLC to effectively operate the Reverse Osmosis (RO) plant. The system maintains the Total Dissolved Solids (TDS) levels of the water by controlling the valves and pumps associated with the feed water, cleaning-in-place (CIP) process, and product water tanks. This automation ensures optimal performance of the RO plant while ensuring water quality meets required standards.

Client: Multi Caps

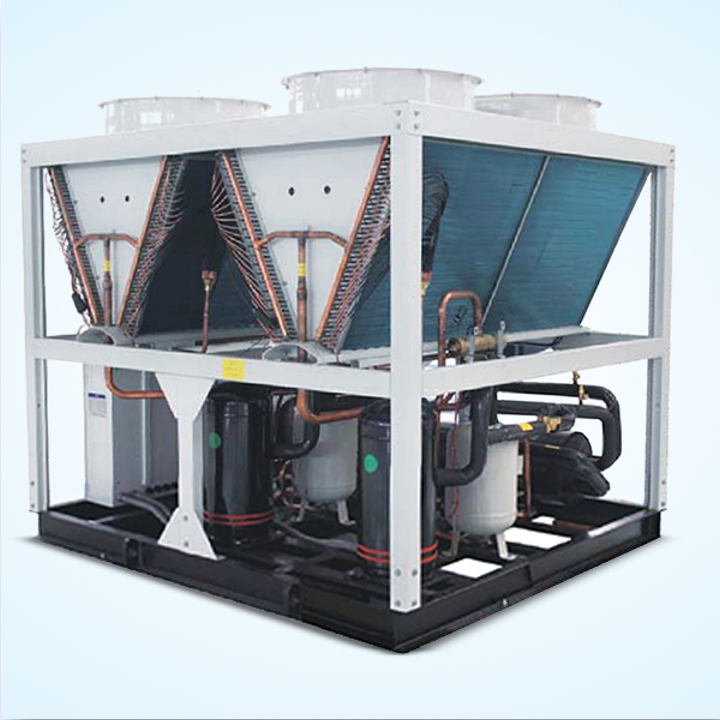

System: Air-cooled Scroll Chiller

- “Programming of a Fatek PLC and Weintek HMI for the control of an air-cooled scroll chiller with dual compressors. The system incorporates comprehensive safety features, including low and high-pressure trips via pressure transmitters on the suction and discharge lines, water flow loss protection, phase sequence protection, and thermal overload protection for both the condenser and compressors. The control algorithm was designed to manage the operation of both compressors based on the leaving chilled water temperature, while electronic expansion valves were regulated by measuring suction superheat. Additionally, compressor run hours were monitored to prevent overloading. As a result, a fully custom control system was developed for efficient operation and maintenance of the chiller.”

Client: Serioplast Pakistan Pvt Ltd

System: Screw Chiller

“Design of a control system for a dual-compressor screw chiller, incorporating Fatek PLC and Weintek HMI. The system includes comprehensive safety mechanisms, such as low and high-pressure trips via pressure transmitters on both the suction and discharge lines, water flow loss protection, phase sequence protection, and thermal overload protection for the condenser and compressors. Additionally, the system features oil level and pressure monitoring to ensure proper lubrication and prevent compressor damage. The control algorithm manages the operation of both compressors based on the leaving chilled water temperature, with electronic expansion valves controlled by measuring suction superheat. Compressor running hours are tracked to prevent overloading. This fully customized control system ensures efficient operation, protection, and maintenance of the screw chiller.”

Client: Shipyard

System: Air-cooled Scroll Chiller

- “Programming of a Fatek PLC and Weintek HMI for the control of an air-cooled scroll chiller with dual compressors. The system incorporates comprehensive safety features, including low and high-pressure trips via pressure transmitters on the suction and discharge lines, water flow loss protection, phase sequence protection, and thermal overload protection for both the condenser and compressors. The control algorithm was designed to manage the operation of both compressors based on the leaving chilled water temperature, while electronic expansion valves were regulated by measuring suction superheat. Additionally, compressor run hours were monitored to prevent overloading. As a result, a fully custom control system was developed for efficient operation and maintenance of the chiller.”

Client: Mehran Bottlers

System: Air-cooled Scroll Chiller

- “Programming of a Fatek PLC and Weintek HMI for the control of an air-cooled scroll chiller with dual compressors. The system incorporates comprehensive safety features, including low and high-pressure trips via pressure transmitters on the suction and discharge lines, water flow loss protection, phase sequence protection, and thermal overload protection for both the condenser and compressors. The control algorithm was designed to manage the operation of both compressors based on the leaving chilled water temperature, while electronic expansion valves were regulated by measuring suction superheat. Additionally, compressor run hours were monitored to prevent overloading. As a result, a fully custom control system was developed for efficient operation and maintenance of the chiller.”

Client: Cool Max

System: Air-cooled Scroll Chiller

- “Programming of a Fatek PLC and Weintek HMI for the control of an air-cooled scroll chiller with dual compressors. The system incorporates comprehensive safety features, including low and high-pressure trips via pressure transmitters on the suction and discharge lines, water flow loss protection, phase sequence protection, and thermal overload protection for both the condenser and compressors. The control algorithm was designed to manage the operation of both compressors based on the leaving chilled water temperature, while electronic expansion valves were regulated by measuring suction superheat. Additionally, compressor run hours were monitored to prevent overloading. As a result, a fully custom control system was developed for efficient operation and maintenance of the chiller.”

Client: Aisha Steel

System: AHU

- Fatek PLC & Weintek HMI to control 4 different motorized dampers in different zones in order to maintain the temperature as per the given setpoint

Client: Union Fabric

System: AHU

Programming of Fatek PLC & Weintek HMI to maintain temperature and humidity by controlling Evaporator Blower speed, Heaters, Humidifiers & Chilled Water Control Valve.

Client: State Bank of Pakistan

System: Breaker Monitoring System

Installed auxiliary monitoring for breakers and provided real-time status monitoring of nearly 100 breakers on an LCD TV.

Installed auxiliary monitoring for breakers and provided real-time status monitoring of nearly 100 breakers on an LCD TV.

Client: Barlo Services (Germany)

System: AHU

Programming of Fatek PLC & Weintek HMI to maintain temperature and humidity by controlling Evaporator Blower speed, Heaters, Humidifiers & Chilled Water Control Valve.

Programming of Fatek PLC & Weintek HMI to maintain temperature and humidity by controlling Evaporator Blower speed, Heaters, Humidifiers & Chilled Water Control Valve.

Client: Shipyard

System: Curing Oven

- Fatek PLC and HMI were used to precisely maintain a temperature of 250°C for 2 hours inside the curing chamber.

Client: Fashionwear Pvt Ltd

System: Dryer Machine

Control the moisture content of clothing material by regulating the chamber’s temperature, humidity, and fabric moisture levels through the control of a steam valve, blower, and machine speed adjustments..

Control the moisture content of clothing material by regulating the chamber’s temperature, humidity, and fabric moisture levels through the control of a steam valve, blower, and machine speed adjustments..

Client: AB Foods

System: Chocolate Moulding Machine

- Fatek PLC Programming & HMI Designing,

- Control of 3 Servo Drive to dose chocolate in moulding machine.

Client: Lucky Paragon

System: Concrete Batching Plant

Provide WinCC SCADA monitoring & control system for a concrete batching plant across four different PCs.

Client: Solarkaz International (Pvt) Ltd

System: Boiler Control System

Programmed Siemens PLC and HMI to control the operations of a boiler plant.

Programmed Siemens PLC and HMI to control the operations of a boiler plant.